Lem Epoxy is actually a variety of adhesive that is definitely noted for its strong bonding Houses and versatility. It is just a two-aspect adhesive, consisting of a resin in addition to a hardener, which have to be mixed with each other in an effort to activate the bonding course of action. The moment blended, Lem Epoxy forms a strong, long lasting bond which is resistant to warmth, h2o, and substances. This makes it a perfect choice for a wide array of purposes, from residence repairs to industrial projects.

Lem Epoxy is available in a variety of formulations, including fast-environment and slow-environment options, along with distinct viscosities to accommodate distinctive purposes. It can be utilized to bond a variety of supplies, together with metallic, Wooden, plastic, glass, and ceramics. This can make it a flexible adhesive which might be useful for a variety of initiatives, from fixing broken house objects to generating intricate crafts and jewelry. Lem Epoxy is additionally obtainable in numerous colours, making it straightforward to find a formulation that matches the colour with the elements currently being bonded.

The way to Use Lem Epoxy

Making use of Lem Epoxy is relatively easy, but it is important to Stick to the company's Recommendations very carefully to be able to reach the ideal final results. The first step is to get ready the surfaces which will be bonded by cleansing them totally to remove any Grime, grease, or other contaminants that could interfere Along with the bonding method. As soon as the surfaces are thoroughly clean and dry, another stage is To combine the resin and hardener together in the right proportions. This can normally be done by squeezing equal quantities of each part on to a disposable surface, like a bit of cardboard, and then mixing them together with a small adhere or spatula.

Once the resin and hardener happen to be totally blended, they should be applied to the surfaces which might be to generally be bonded. It is vital to work promptly at this time, as Lem Epoxy contains a minimal Doing the job time before it begins to set. The adhesive needs to be utilized evenly to both equally surfaces, after which you can The 2 surfaces should be pressed together firmly to make sure an excellent bond. It is necessary to hold the surfaces in position until finally the adhesive has set, which might get anywhere from a few minutes to several several hours, according to the formulation of Lem Epoxy being used.

Benefits of Lem Epoxy

Lem Epoxy features many Gains which make it a preferred choice for bonding purposes. Among the list of key advantages of Lem Epoxy is its strength and longevity. After cured, Lem Epoxy types a bond that's immune to heat, water, and substances, making it suited to use in an array of environments. This can make it an excellent choice for apps in which a solid, prolonged-lasting bond is needed.

An additional good thing about Lem Epoxy is its flexibility. It can be utilized to bond an array of elements, such as steel, Wooden, plastic, glass, and ceramics. This causes it to be a flexible adhesive that may be useful for a wide range of initiatives, from household repairs to industrial apps. In addition, Lem Epoxy is obtainable in various formulations to fit diverse purposes, such as rapid-location and slow-environment selections, in addition to distinct viscosities and colours.

Purposes of Lem Epoxy

Lem Epoxy has a wide range of programs on account of its toughness, longevity, and flexibility. It can be used for family repairs, for example correcting damaged ceramics or restoring picket furniture. It is also generally Utilized in industrial settings for bonding metal elements or producing composite resources. Moreover, Lem Epoxy is well-known inside the crafting and jewelry-producing industries as a result of its capability to bond an array of supplies and its availability in different colors.

One popular software of Lem Epoxy is while in the automotive sector, in which it really is utilized for bonding steel parts and restoring plastic components. It's also frequently Employed in development for bonding concrete and masonry resources. In addition, Lem Epoxy is usually Employed in maritime purposes on account of its resistance to water and substances. Total, Lem Epoxy has a wide range of purposes across many industries on account of its strength, toughness, and versatility.

Guidelines for Working with Lem Epoxy

When dealing with Lem Epoxy, there are lots of tips which will help make sure the greatest results. It is necessary to follow the producer's Guidance very carefully so that you can accomplish the ideal bond strength and sturdiness. This incorporates preparing the surfaces effectively by cleansing them comprehensively and mixing the resin and hardener in the correct proportions.

Additionally it is essential to work rapidly when employing Lem Epoxy, as it's got a confined working time just before it starts to established. This means that it is vital to own all the required instruments and elements organized right before mixing the adhesive. In addition, it is important to apply the adhesive evenly to both surfaces and push them alongside one another firmly to be certain a very good bond.

Protection Safety measures when Employing Lem Epoxy

Even though Lem Epoxy is a versatile and efficient adhesive, it can be crucial to acquire proper safety precautions when using it. This features putting on gloves and eye safety when handling the adhesive so that you can guard the skin and eyes from connection with the resin and hardener. It is additionally crucial that you function in a very well-ventilated location when using Lem Epoxy so as to stay away from inhaling any fumes Which might be presented off throughout the curing system.

Comparing Lem Epoxy with Other Adhesives

When evaluating Lem Epoxy with other adhesives, there are numerous things to look at. One of many most important advantages of Lem Epoxy is its energy and longevity. When cured, it varieties a bond that's proof against warmth, h2o, and chemical substances, which makes it well suited for use in an array of environments. Moreover, Lem Epoxy is available in numerous formulations to match distinctive applications, which includes rapidly-location and gradual-setting alternatives, and also distinctive viscosities and colours.

Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Patrick Renna Then & Now!

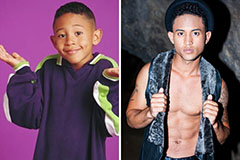

Patrick Renna Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!